Wastewater package plants offer a compact and efficient solution for treating wastewater in various settings. This article reviews what a wastewater package plant is and the different types, such as extended aeration, oxidation ditches, and contact stabilization. Understanding these systems helps in effective deployment of wastewater treatment and also compliance with environmental regulations.

What is a Wastewater Package Plant

A wastewater package plant is a prefabricated treatment plant that does everything a centralized plant does to break down wastewater. Moreover, it can separate physical, biological, metallic, and other wastes from the water. Because it is a turnkey solution, wastewater package plant benefits residential and industrial setups and remote locations where full-scale plants are technically and economically unfeasible. Some key features of package plants include:

- Modular Design: Package plants often come in modular components that are easy to assemble on-site. Thus, allowing for scalability and customization to meet the specific needs of the application.

- Compact Size: The design of package plants occupies minimal space, making them ideal for remote or constrained locations.

- Pre-engineered Systems: These are usually prefabricated. As a result, they provide less installation time and costs than conventional wastewater treatment facilities.

Components of a Wastewater Package Plant

Although the parts of a package plant vary according to the type, there are some standard features across all types. Some of these components include:

- Influent Screening: Removes large solids and also debris from the incoming wastewater.

- Aeration Chamber: Adds oxygen to the wastewater to support the biological treatment process.

- Clarification Tank: Allows solid particles to settle out of the treated water.

- Disinfection Unit: Ensure harmful pathogens are removed before discharging the treated water.

- Sludge Management: Handles the byproducts of the treatment process.

Types of Wastewater Package Plant

Wastewater package plants differ in their processing mechanism, construction, and treatment capabilities. However, the common types are extended aeration, sequencing batch reactor, oxidation ditches, contact stabilization, and rotating biological contactor.

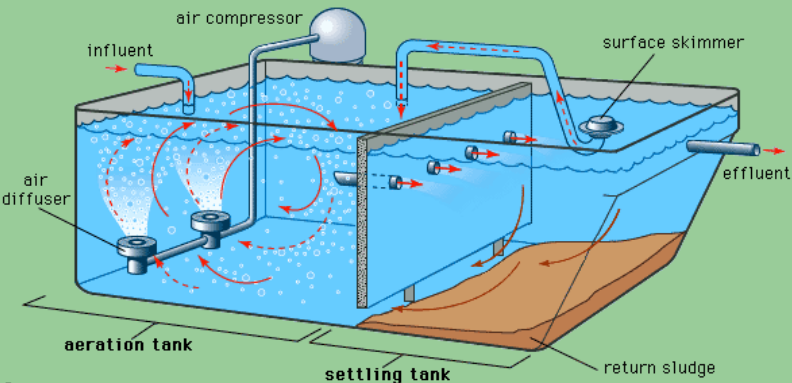

Extended Aeration Plants

This type of plant treats organic waste under aerobic conditions. It achieves this by mixing water with compressed air as it enters an aeration tank, thus promoting the growth of aerobic bacteria that degrade organic matter over an extended period. Meanwhile, control of the pH level and nutrients for biological growth are equally important during the treatment process.

An extended aeration plant is ideal for biodegradable waste, including domestic sewage, food processing waste, and some industrial wastewater. Likewise, these types of wastewater have low to moderate levels of organic pollutants (measured as Biochemical Oxygen Demand or BOD).

Advantages of Extended Aeration Plants

- Low sludge production.

- Robust as well as reliable structure.

- Cost-effective.

- High organic matter removal rate.

- It is capable of handling fluctuations in flow as well as organic load.

Disadvantages of Extended Aeration Plants

- Large footprint in comparison to other package plant systems.

- It is an energy- and time-intensive process.

- Also, it is unsuitable for treating high-strength industrial wastewater.

- Potential for odor and noise issues.

Sequencing Batch Reactors

Sequencing Batch Reactor (SBR) package plants treat the wastewater in batches rather than continuous flow. It achieves this using a series of steps within a single reactor tank. The aeration and sedimentation are carried out in the same tank. Besides, an equalization tank controls the flow and load before sending the batches into the treatment tank. Generally, PCB logic controllers automate the different treatment processes inside the tank at regular intervals. The typical steps in SBR treatments include fill, react, settle, decant, and also idle phases with flow rates between 0.01 and 0.2 MGD.

Advantages of Sequencing Batch Reactors

- SBRs can easily adjust to changes in influent flow as well as load.

- Also, its single-tank treatment makes the design compact and flexible.

- High levels of waste and nutrient removal.

- Aeration requirement is only during specific phases, thus allowing for energy savings.

Disadvantages of Sequencing Batch Reactors

- SBRs require sophisticated control systems, as well as skilled operators.

- Regular removal and handling of excess sludge are mandatory to maintain system efficiency.

Oxidation Ditches

Oxidation ditches are activated sludge treatment systems that employ a continuous loop, channel, or ditch for the biological treatment of wastewater. Moreover, this type of wastewater package plant features one or multiple channels arranged in a ring, oval, or horseshoe-shaped basin. Meanwhile, aerators that can be mounted horizontally or vertically achieve aeration, circulation, and oxygen transfer in the ditch.

Advantages of Oxidation Ditches

- It can process wastewater with uniform levels as well as continuous discharge.

- Low sludge production.

- The robustness of the plant can handle shock loads or hydraulic surges.

- Lower capital and operating costs than other complex treatment systems.

Disadvantages of Oxidation Ditches

- Requires a relatively larger space.

- Continuous aeration requirements, thus, higher energy costs.

Contact Stabilization

It is a variation of the conventional activated sludge process designed to improve efficiency and also reduce the aeration tank volume required for wastewater treatment. Moreover, this type of wastewater package plant separates the stages of biological contact and sludge stabilization into two distinct tanks. So, it improves efficiency and facilitates the effective use of biomass.

Advantages of Contact Stabilization

- It reduces the volume of aeration tanks, thus, saving space and cost.

- Contact stabilization provides rapid responses to changes in wastewater characteristics.

- Also, low aeration time reduces energy consumption.

Disadvantages of Contact Stabilization

- The plant needs careful management and also monitoring of the two distinct phases.

- It requires adequate odor control measures.

- Regular removal of excess sludge is necessary.

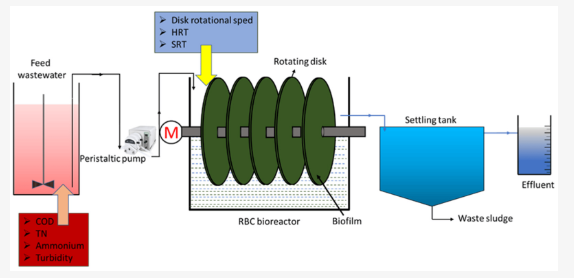

Rotating Biological Contactor

Rotating Biological Contactors (RBCs) are fixed-film wastewater treatment plants that use a series of closely spaced, rotating disks mounted on a horizontal shaft. Moreover, these disks support the growth of biofilm that degrades organic matter in the wastewater. The disks rotate through the wastewater and air, thus providing the necessary oxygen for the biological processes. Moreover, RBCs treat wastewater post-sedimentation once all the biomass waste is settled.

Advantages of Rotating Biological Contactor

- Simple to operate and also maintain.

- It also has excellent stability and resistance to hydraulic shocks.

- Zero risk of channeling and related issues.

- The rotational aeration process reduces energy consumption.

Disadvantages of Rotating Biological Contactor

- High upfront as well as maintenance costs.

- Although consumption is low, a continuous electricity supply is necessary to run the plant.

- The RBCs are thermal sensitive because temperature fluctuations can impact treatment efficiency.

Wastewater Package Plant Controls

At PCTX, we offer control solutions that complement the deployment of wastewater package plants. Moreover, PCTX specializes in providing advanced electrical equipment and services that enhance the performance and efficiency of these plants. Our offerings include:

- Switchgear/Motor Controllers: Ensures reliable power distribution, as well as motor control for the operation of valves and ancillary equipment.

- MV Switchgear/MCC: Facilitates medium voltage applications crucial for operating wastewater treatment components.

- Power and Distribution Transformers: Provides necessary power transformations to support plant operations.

- Preventive Maintenance Services: Our engineers develop and also deploy preventive maintenance schedules. Thus, ensuring longevity and efficiency of electrical systems within wastewater treatment plants.

Contact Us for your wastewater package plant electrical equipment needs.