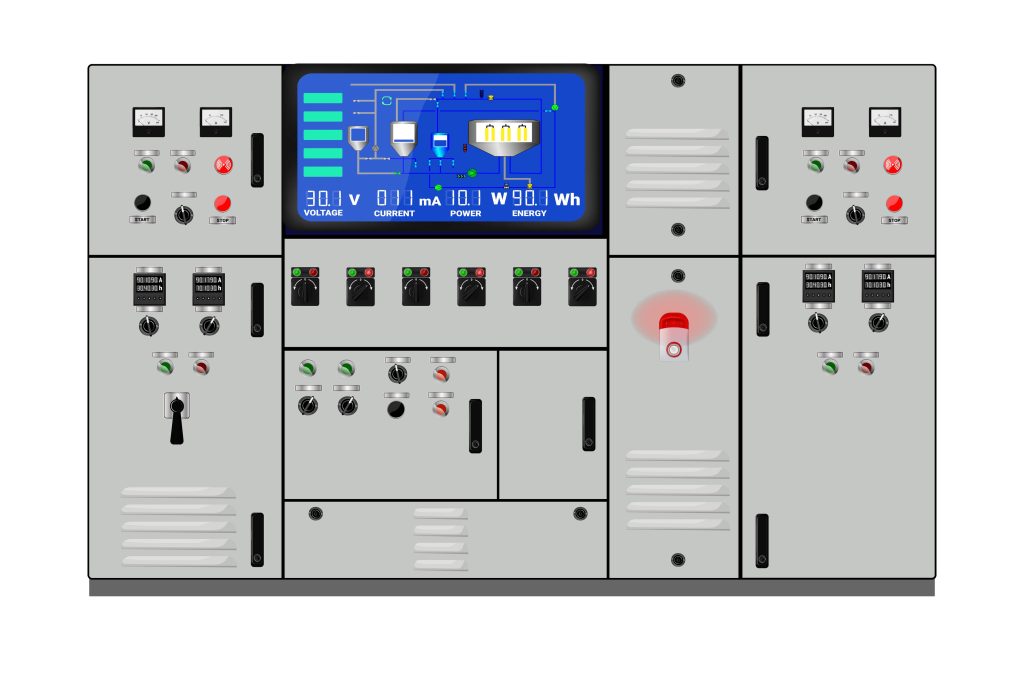

Motor Control Centers

Customized Motor Control Centers for Efficient and Safe Integration

At Paradigm Controls of Texas (PCTX), we design and build custom Motor Control Centers (MCCs) tailored to your specific motor control needs. Available in both low voltage (LV) and medium voltage (MV) configurations, our MCCs streamline installation, reduce wiring complexity, and enhance safety. For seamless integration, MCCs can also be housed inside Power Distribution Centers (PDCs), thus making them ideal for industrial plants and large commercial facilities.

What Does a Motor Control Center Do?

MCCs serve as centralized systems for managing multiple electric motors from a single location. Since every application is different, we tailor each MCC to match your project’s scale, motor count, and control requirements. Common functions include:

- Power Distribution: MCCs distribute power from a central source to individual motors or motor groups throughout your facility.

- Motor Operation and Speed Control: MCCs manage motor start/stop functions and can regulate speed using contactors, motor starters, or Variable Frequency Drives (VFDs).

- Overload and Fault Protection: Built-in protection devices—like thermal or electronic overload relays—help prevent motor damage due to current overloads or electrical faults.

- Remote Monitoring and Diagnostics: Modern MCCs support remote access, diagnostics, and real-time monitoring, reducing maintenance time and improving system reliability.

Essential Components of Motor Control Centers

While each MCC from Paradigm Controls is custom-built, most units include the following key components:

Power Busbars

High-conductivity copper or aluminum bars that distribute incoming electrical power to the motor control units. These are engineered to safely handle high current loads.

Motor Starters

Devices that initiate and stop motor operation while providing overload protection. Starters typically include contactors and thermal or electronic relays.

Variable Frequency Drives (VFDs)

Also known as adjustable frequency drives, these components regulate motor speed and torque by controlling voltage and frequency—boosting energy efficiency and operational flexibility.

Control Circuit Components

Includes relays, pushbuttons, timers, and other control devices for managing motor functions. Advanced MCCs may also feature Programmable Logic Controllers (PLCs) or Programmable Automation Controllers (PACs) for automated processes.

Enclosures

Rugged enclosures house all MCC components, providing environmental protection and preventing unauthorized access. Our designs are suitable for both indoor and outdoor applications, and built from high-quality steel or aluminum.

Types of Motor Control Centers

Choosing the right MCC type depends on your application, safety requirements, and desired level of automation. Paradigm Controls offers:

Conventional Motor Control Centers

These units feature fixed motor control compartments in a common enclosure. They are ideal for facilities with a stable number of motors and minimal need for system reconfiguration.

Intelligent Motor Control Centers (iMCCs)

iMCCs incorporate advanced communication and control technologies. Features include remote monitoring, predictive maintenance, and real-time diagnostics—making them highly efficient and adaptable to modern industrial operations.

Arc Resistant Motor Control Centers

Designed for maximum personnel and equipment safety, these MCCs contain and redirect arc flash energy away from the operator. Reinforced structures, pressure-relief vents, and isolation barriers reduce the risk of injury and damage during fault conditions.

Why Work with Paradigm Controls?

When it comes to motor control, experience and customization matter. Our team offers:

- In-house engineering for tailored MCC design.

- Compliance with UL, IEEE, ANSI, and NEC standards

- Integration with PDCs for turnkey power distribution solutions.

- Ongoing support from concept to commissioning

Let’s work together to build a high-performance MCC solution that fits your operation perfectly. Contact us today for consultation or to get a quote.

Our Trusted Vendors