Gas insulated switchgear and air insulated switchgear are two common types of electrical switchgear, each with distinct advantages and applications. This article compares gas insulated switchgear vs air insulated switchgear, discussing their features, benefits, limitations, and ideal use cases. Understanding the differences between gas insulated and air insulated switchgear can help in selecting the best option for specific electrical infrastructure needs.

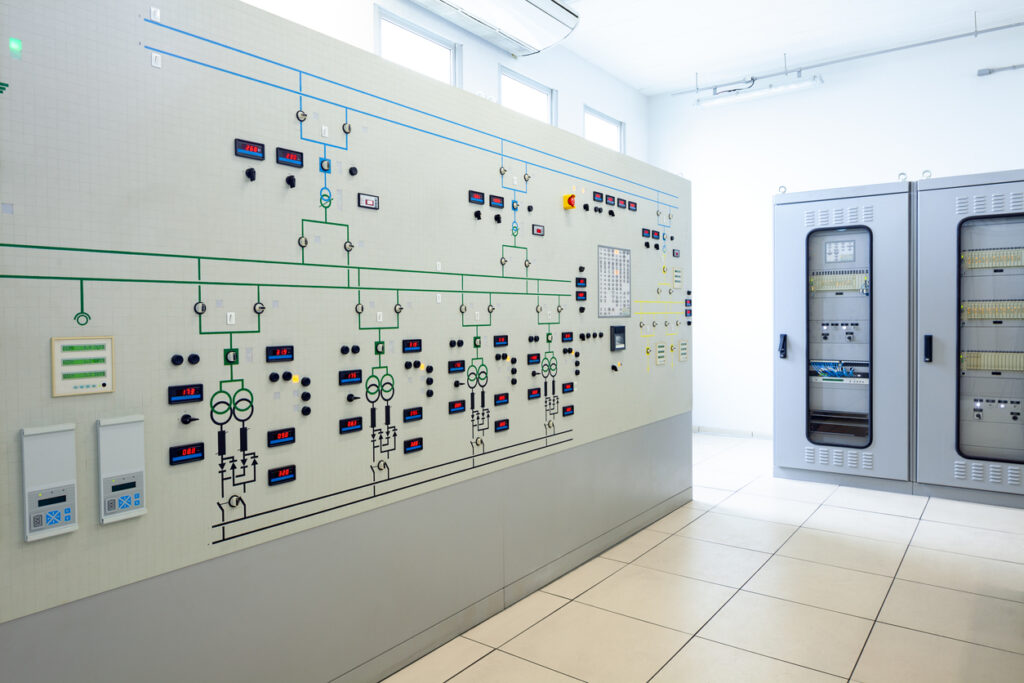

Air Insulated Switchgear

The air insulated switchgear (AIS) uses atmospheric air as the primary dielectric medium to insulate electrical components from each other. AIS is the predominant type of switchgear due to its simplicity and cost-effectiveness, with deployments in almost 70% of substations globally. Moreover, like other switchgear types, AIS consists of busbars, circuit breakers, disconnectors, and instrument transformers within metal-enclosed compartments. However, each compartment is exposed to the atmosphere, with appropriate spacing between components to prevent arcing and faults.

How Does Air-Insulated Switchgear Work?

Air-insulated switchgear uses “air” as the primary insulating medium between live components, which helps prevent electrical arcs and shorts in case of any circuit faults. Safety is maintained in this switchgear by:

- Air Insulation: All components in air insulated switchgear (AIS) are assembled within metal-enclosed compartments, using air as the insulating medium. However, it is necessary to maintain a minimum spacing between component mountings based on the system voltage rating.

- Fault Occurrence: When protective relays detect the faults, the circuit breaker is activated and it interrupts the current flow. Thus, preventing damage to the system and ensuring safety.

- Arc Quenching: When the arc forms, the air cools and deionizes the arc path as it passes through the arc extinguishing chamber.

Advantages of Air-Insulated Switchgear

- Cost-Effective: AIS is generally less expensive to install and maintain compared to GIS.

- Simplicity: The design and construction of AIS are straightforward, hence, making it easier to understand and operate.

- Easy Access: The open design of AIS allows for easier inspection, maintenance, as well as repairs.

- Flexibility: It is easy to integrate modifications and expansion to meet evolving system requirements.

- Environmentally Friendly: They offer no risk of pollution to the environment.

Disadvantages of Air-Insulated Switchgear

- Large Footprint: AIS occupies more space due to the need for adequate air clearance between components.

- Environmental Exposure: Also, they are more susceptible to environmental conditions such as dust, humidity, and pollution, which can affect performance. So, AIS normally serve indoors and in controlled environments.

- Higher Maintenance: The open design of AIS components necessitates regular maintenance to ensure reliability as well as performance.

Applications of AIS

The air-insulated switchgear is commonly used in rural or suburban areas where space footprint is not a concern.

- Industrial facilities with low-voltage electrical networks (up to 24 KV).

- Power and auxiliary substations

- Marine structures like container ships, offshore platforms, cruise ships, etc.

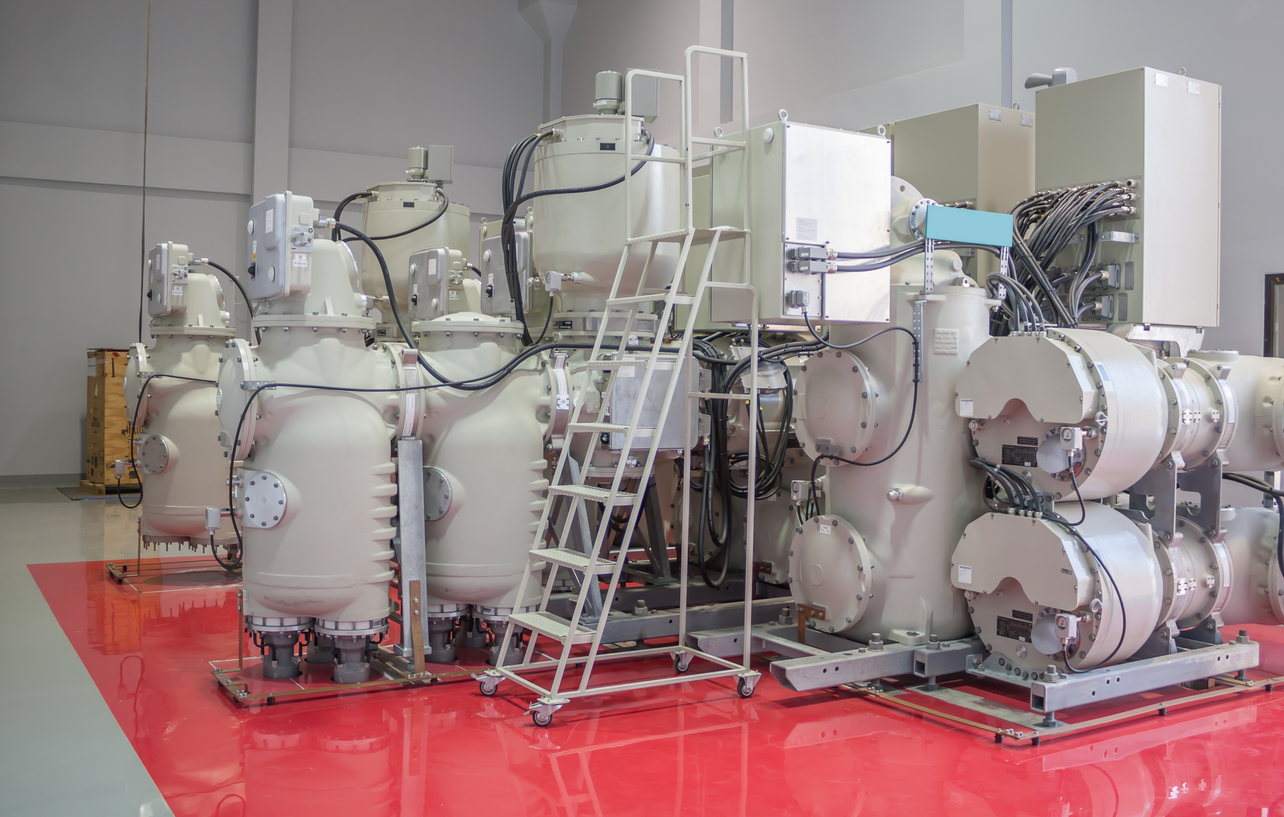

Gas Insulated Switchgear

As the voltage ratings of switchgear go up, it becomes difficult to maintain safety using just air insulation. Hence, necessitating a switch to gas insulated switchgear (GIS). GIS, as the name suggests, utilizes sulfur hexafluoride (SF6) gas as the primary dielectric medium for insulation. The switchgear components are in different modules encapsulated in an air-tight enclosure that is pressurized with SF6, thus providing a single insulation system.

How Does Gas Insulated Switchgear Work?

The working principle of gas insulated switchgear is similar vs air insulated switchgear, but the insulation medium differs. In GIS, the SF6 gas cools and insulates the electrical components, preventing electrical arcs as well as ensuring safe operation. While the switchgear operates by opening and closing circuits to control and protect electrical equipment.

Advantages of GIS

- Compact Design: The dielectric strength of SF6 gas is 2.5 times higher than air. So, the size of gas insulated switchgear is significantly smaller vs its air insulated counterpart.

- High Reliability: The sealed design protects components from environmental conditions, thus reducing the risk of faults and failures.

- Low Maintenance: GIS requires less frequent maintenance due to its sealed construction and protection from contaminants.

- Safety: The use of SF6 gas ensures effective insulation and arc quenching, especially when handling higher voltages..

Disadvantages of GIS

- High Cost: Gas insulated switchgear is generally more expensive to install and maintain vs air insulated switchgear.

- SF6 Handling: SF6 gas is a potent greenhouse gas, so its handling and disposal require strict regulations and precautions.

- Complexity: GIS systems are more complex and, therefore require specialized knowledge for operation and maintenance.

Applications of GIS

- GIS is ideal for installations where pollution and chemical contamination are high. For example, a petrochemical refinery.

- High voltage applications such as transmission and distribution systems.

- Underground electrical networks like in the metro, tunnel roads, and underground substations.

- Performance-sensitive applications like data centers that require high reliability.

Differences Between Gas Insulated Switchgear and Air Insulated Switchgear

| Aspect | Air Insulated Switchgear (AIS) | Gas Insulated Switchgear (GIS) |

| Insulation Medium | Ambient air | Sulfur hexafluoride (SF6) gas |

| Space Requirement | Large footprint | Compact design |

| Reliability | Pollution, humidity, as well as other environmental factors can affect insulation | Environmental influence is negligible, thus, high reliability |

| Installation | Longer installation time | Shorter installation time |

| Maintenance | Higher maintenance due to exposure to the atmosphere | Low maintenance |

| Cost | Lower initial cost but higher long-term maintenance | Higher initial cost but lower long-term costs |

| Modifications | Generally, it is easy to integrate additional units via a simple extension process | Less flexible toward extension and upgrades |